Professional Projects

Customer Satisfaction Metric shift

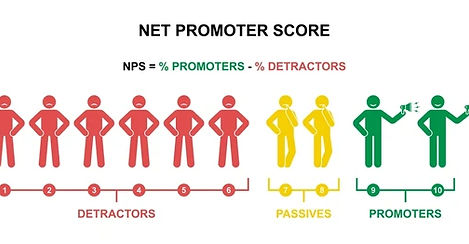

Led the transition from Customer Satisfaction Index (CSI) to Net Promoter Score (NPS), leveraging L1 and L2 drivers for deeper insights and effective identification of improvement areas.

TPM Certification Pilot

Led the TPM certification initiative for East Region dealerships, successfully guiding 6 out of 8 outlets to certification. This involved conducting gap assessments, implementing process improvements, and driving engagement across dealer teams. Enhanced 37 critical KPIs including equipment uptime, service lead times, and first-time fix rates, significantly improving overall service quality and operational efficiency.

Customer Facility Mapping

Identified poor customer lounge conditions as a key root cause of dissatisfaction in service workshops. Initiated and led an upgrade campaign across all 43 dealers and sub-dealers in the network. Faced initial resistance from stakeholders, but effectively communicated the long-term impact on customer retention and brand perception. Post-implementation, the territory achieved the highest Net Promoter Score (NPS) across PAN India, validating the initiative’s success in enhancing the customer experience.

NPD Support for TVS Raider

As part of the NPD team, I was responsible for overseeing the field performance of the TVS Raider during its critical first year post-launch—a period characterized by high initial failure rates as per the bathtub curve. I tracked defect trends, coordinated with service teams for real-time issue resolution, and implemented feedback loops with engineering to drive early product stabilization. This proactive support helped reduce failure incidents and ensured a smoother transition into the product maturity phase.

Process Optimization Using DFSS for Leakage Reduction

Conducted a comprehensive analysis of 275 IDI leakage cases across three powertrain assembly lines. Utilized Design for Six Sigma (DFSS) methodologies to create and refine PFMEA sheets, enabling structured identification of potential failure modes. Implemented targeted action plans based on process assessments, leading to the resolution of key issues and a measurable improvement in operational efficiency and line reliability.

Research Project

This research focused on optimizing key parameters—weld velocity, tool tip depth, and tool diameter—for forward steel welding involving brass as the interface material. Through experimental trials and statistical analysis, critical thresholds were identified that significantly enhanced material bonding quality. The optimized settings led to a 25% improvement in joint performance while maintaining high process efficiency. The findings contribute to advancing hybrid material welding techniques in automotive and structural applications.

Academic Projects

-

Mangonel Arm and Holder Redesign for 30% Range Improvement

Optimized arm length and holder configuration to enhance catapult performance through material and mechanical refinements.

-

Arduino Line Follower and Obstacle-Avoiding RoboCar with Xbee

Built a microcontroller-based autonomous robot with accurate path tracking and wireless obstacle detection.

-

Cam and Follower Mechanism Model for Engine Simulation

Created a working model to demonstrate valve timing and motion transmission in internal combustion engines.

-

Small-Scale Truss Design for Strength and Cost Optimization

Designed and tested a lightweight truss structure to evaluate load-bearing capacity against material costs.